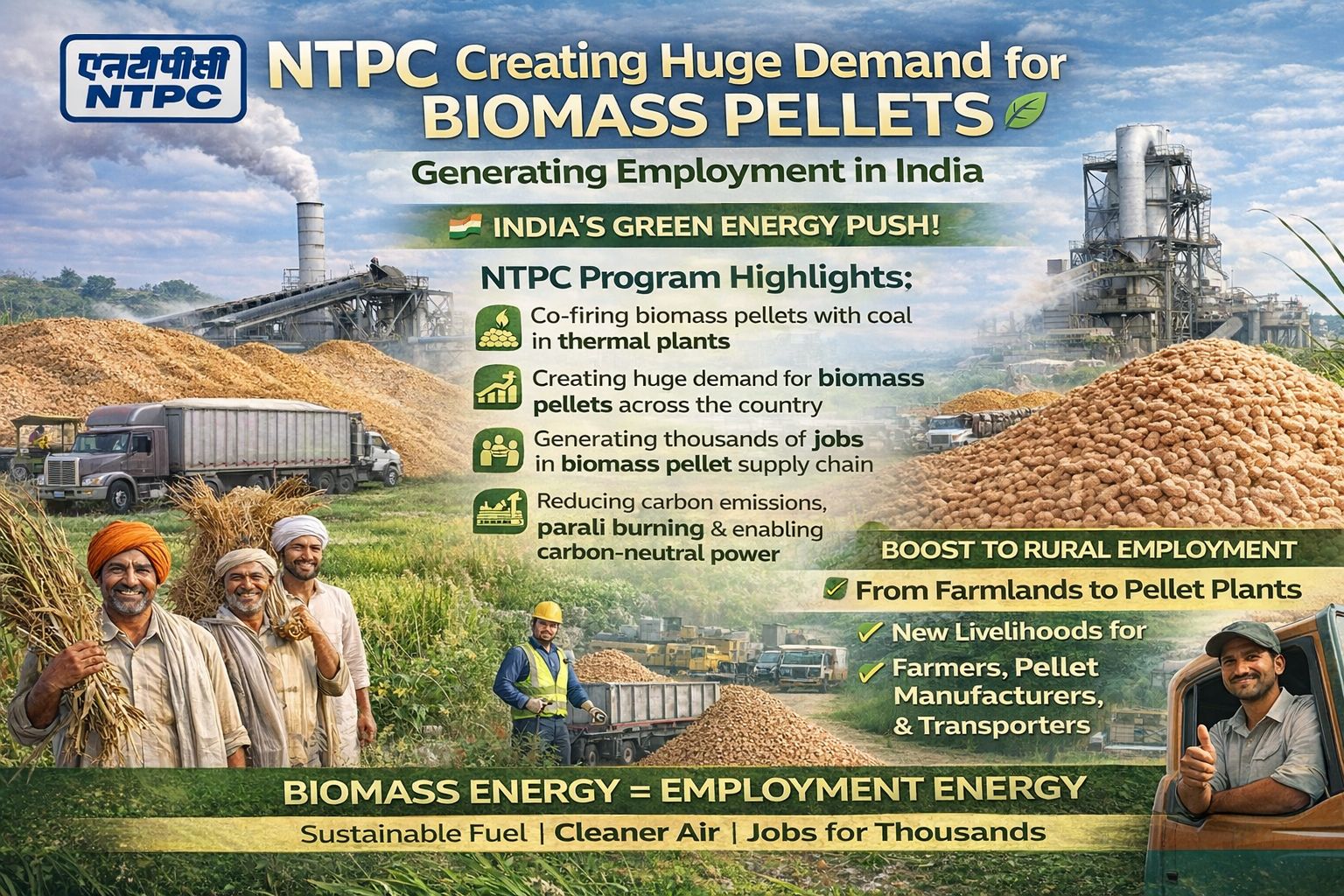

This strategic shift is not only reducing India’s dependence on fossil fuels but is also creating massive demand for biomass pellets, unlocking large-scale employment opportunities, and providing a sustainable solution to the long-standing problem of crop residue burning.

India’s Shift Towards Biomass Co-Firing

India’s thermal power sector has traditionally relied on coal, but rising environmental concerns and global decarbonization targets have prompted a transition towards cleaner alternatives. Biomass pellets—manufactured from agricultural residues such as paddy straw, rice husk, mustard straw, and other agro-waste—have emerged as a viable and scalable solution.

NTPC has actively adopted biomass co-firing, blending biomass pellets with coal in thermal power plants. This approach:

Reduces greenhouse gas emissions

Cuts down particulate pollution

Helps achieve carbon-neutral power generation targets

Supports India’s renewable and clean energy commitments

Massive Demand for Biomass Pellets Across India

With NTPC and other thermal utilities increasing the percentage of biomass co-firing, the demand for biomass pellets has grown exponentially. This has resulted in:

Continuous and long-term pellet procurement requirements

Creation of dedicated biomass pellet supply chains

Strong market visibility for pellet manufacturers

States with abundant agricultural residue—such as Uttar Pradesh, Bihar, Punjab, Haryana, Madhya Pradesh, Chhattisgarh, Odisha, Maharashtra, Andhra Pradesh, and Telangana—are emerging as key biomass pellet production hubs.

Employment Generation: From Farms to Pellet Plants

One of the most impactful outcomes of NTPC’s biomass initiative is employment generation, particularly in rural and semi-urban India.

Direct Employment Opportunities

Biomass pellet plant operations

Skilled and semi-skilled plant manpower

Machine operators, technicians, and supervisors

Indirect Employment Opportunities

Farmers supplying crop residues

Aggregators and storage operators

Transporters and logistics providers

Equipment manufacturers and service providers

This ecosystem is creating thousands of jobs, improving rural incomes, and strengthening the agricultural value chain.

A Sustainable Solution to Parali Burning

Crop residue burning, especially paddy straw burning, has been a major environmental and health concern in North India. Biomass pelletization provides a practical and profitable alternative by converting waste into valuable fuel.

Benefits include:

Reduction in stubble burning

Cleaner air and improved public health

Additional income for farmers

Environmentally responsible waste management

Economic Opportunities for Entrepreneurs and Investors

The growing demand from NTPC and other power producers has opened new avenues for:

Entrepreneurs setting up biomass pellet plants

Rice millers and agro-processors diversifying revenue streams

Investors entering the green energy and biofuel sector

With policy support, assured demand, and scalable technology, biomass pellet manufacturing has become one of the most promising green businesses in India today.

Biomass Energy: Fueling India’s Green Growth

The biomass pellet ecosystem aligns with multiple national priorities:

Clean energy transition

Rural employment generation

Farmer welfare and income diversification

Reduction in carbon emissions

Sustainable industrial growth

Biomass energy is no longer just an alternative fuel—it is becoming a strategic pillar of India’s energy and employment policy.

Conclusion: Biomass Pellets as Employment Energy

NTPC’s proactive push towards biomass co-firing is transforming India’s power sector while simultaneously strengthening the rural economy. By creating huge demand for biomass pellets, NTPC is enabling a win-win model—cleaner energy for the nation and sustainable livelihoods for thousands.

As India moves towards a greener future, biomass pellets stand out as a powerful solution that connects agriculture, industry, employment, and sustainability into one integrated ecosystem.